Everyone in construction knows the arithmetic: we pour a staggering amount of concrete every year, and a lot of it doesn’t last as long as we wish. Repairs arrive early, maintenance eats budgets, and the carbon bill keeps growing. So when engineers look back to Rome, it’s not out of nostalgia. It’s a search for techniques that stretch service life, cut clinker, and make every tonne of binder count.

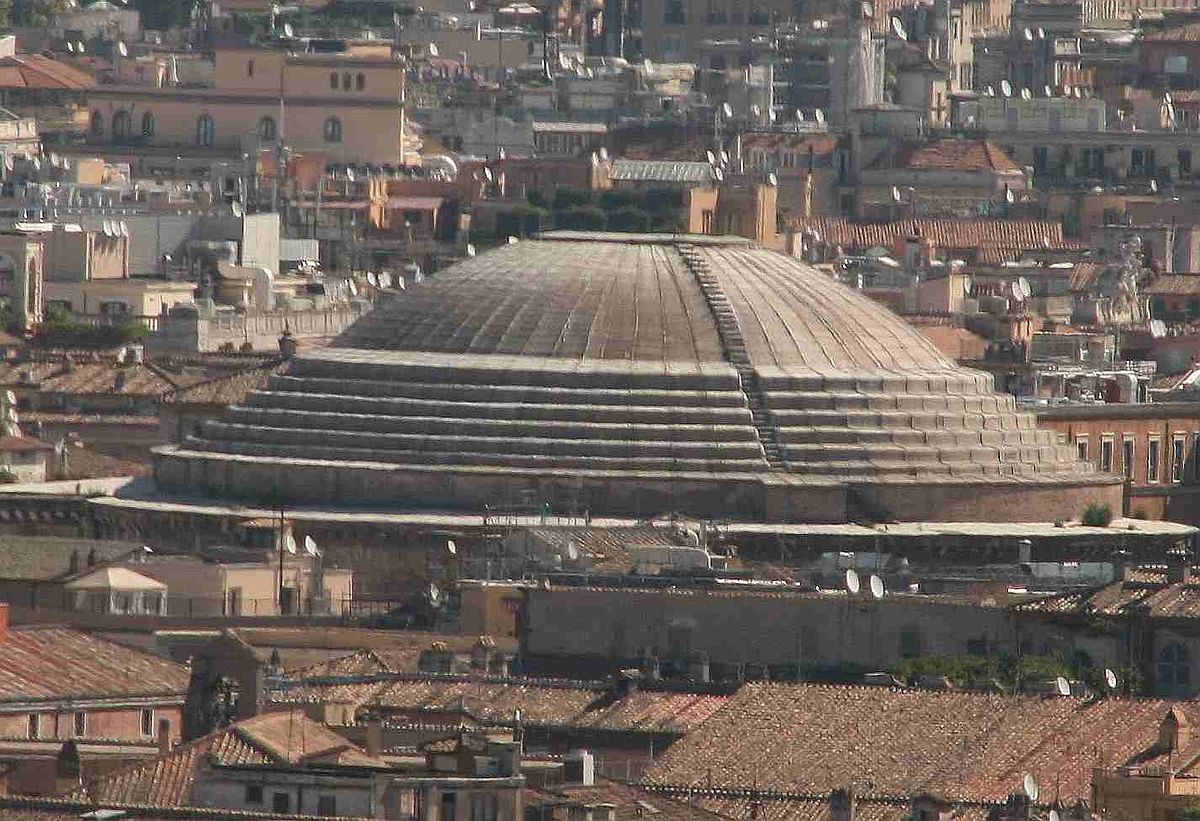

Roman builders worked with lime and volcanic ash rather than modern Portland cement. The result was a family of pozzolanic concretes that hardened slowly but produced binders remarkably resilient to time, salt, and water. The Pantheon’s dome is the poster child, but harbours, aqueducts, and bathhouses tell the story just as well. If you’re trying to lower emissions in the twenty-first century, durability per kilogram of CO₂ starts to look like the metric that matters.

What made Roman concrete different

Strip the recipe to essentials and you get lime (from heated limestone) blended with reactive volcanic ash. Mix with water and aggregate and the ash reacts with the lime to form strong, long-lived binding gels. Modern Portland cement also relies on calcium-silicate hydrates, but it’s made by firing limestone and clay together at far higher temperatures, generating large process emissions and fuel emissions at once.

Roman practice varied by site. For land structures they used light aggregates and clever grading; for marine works they tipped wooden boxes full of ash and lime into seawater and let chemistry do the rest. The match between material and environment was deliberate. Where we often standardise and push the material to fit the job, Roman builders tuned the job to fit the material.

Why this matters for carbon

Cement production still accounts for a sizeable share of global CO₂. Two streams drive that total: the chemical release of CO₂ when limestone is calcined, and the fuel burned to heat kilns. You can chase both with carbon capture and cleaner energy, but there’s another lever: use less clinker in the first place and make structures last far longer so you rebuild less often.

That’s where Roman-style thinking helps. Pozzolans—materials rich in reactive silica and alumina—let you replace part of the Portland clinker. Natural volcanic ashes, calcined clays, and finely ground industrial by-products can all play the Roman role of ash in the mix. Lower clinker factor means lower immediate emissions; improved durability means fewer repairs and replacements over the life of the asset. The climate benefit compounds over decades.

Chemistry in slow motion

Watch a Roman-inspired mix cure and you’ll notice a different tempo. Early strength can be modest, then the curve bends upwards as the pozzolanic reaction builds fine-grained gels that lock aggregate in place. In marine concretes, seawater gets involved: specific minerals can grow in the matrix, tightening the microstructure rather than tearing it apart. It’s the opposite of what happens to steel-reinforced concrete when chloride ions creep in and corrosion finds a foothold.

There’s another piece of the puzzle: unreacted bits of lime inside the ancient matrix that seem to act like tiny repair depots. When microcracks form, water reaches these pockets and triggers late reactions that stitch the crack. We call it autogenous healing today; the Romans didn’t name it, they just benefited from it.

Translating old practice into modern specs

Bringing Roman logic into present-day projects isn’t about copying a single recipe. It’s about principles:

- Replace clinker with reactive fines. Use natural pozzolans, calcined clays, or blended cements tuned for durability. The goal is a meaningful drop in clinker content without compromising performance.

- Design for the environment. Marine wharves, splash-zone piles, sprayed linings, long-span decks—each exposure category wants a different binder blend and curing regime.

- Aim for dense microstructures. Lower permeability slows chloride ingress and sulphate attack. Pozzolans consume free lime and refine pores; that reduces long-term risk.

- Accept a slower early-age schedule. If you can stage erection to allow longer cure, you get better long-term strength and tighter matrices. Speed isn’t free; it often shows up later on the balance sheet as maintenance.

In other words, shift the conversation with clients from “How fast can we strip formwork?” to “How long until we need a major repair?” The carbon answer lives in that second question.

Where Roman-style mixes shine

Coastal and port works. There’s a reason Roman piers lasted: pozzolanic binders resist seawater far better than ordinary cement paste. Designs that minimise steel, use stainless or FRP in critical spots, and rely on dense, ash-rich matrices can outlast a generation of standard builds.

Mass concrete and thick sections. Dams, foundations, and large footings benefit from low-heat binders. Pozzolans curb peak temperatures and reduce thermal cracking—another lifecycle win.

High-temperature or sulphate-rich environments. Pozzolanic reactions mop up the free lime that would otherwise feed damaging salt reactions. It’s chemistry as prevention, not patching.

The durability dividend

Longevity is a carbon strategy. If a quay lasts one hundred years instead of forty, the emissions tied to replacement vanish from two accounting cycles. If a car park deck shrugs off chlorides because its pores are tight and its rebar strategy is smarter, you avoid decades of patch-and-paint. When owners see repair intervals lengthen, they start asking for the mix again. That’s how old ideas become standard practice: not by romance, but by spreadsheets.

It’s worth saying clearly: low-carbon does not mean low-performance. The trade-off, if there is one, sits mostly at the construction schedule. A slower early cure and careful curing control are the price of a structure that behaves better for the rest of its life. In public projects, that bargain often pays for itself where disruption is costly and access is limited.

Steel, chlorides, and a different path

Modern concrete’s Achilles’ heel is the quiet war between chloride ions and steel. Once corrosion starts, cracks follow, and maintenance cycles accelerate. Roman concretes didn’t rely on steel. We don’t have that luxury for long spans and slender sections, but we can be selective. In the most aggressive exposures, designers are already swapping to corrosion-resistant reinforcement, moving steel away from the surface, or using non-metallic bars where feasible. Pair those choices with a pozzolanic binder and the risk curve flattens.

Supply, standards, and the real-world frictions

Natural pozzolans aren’t evenly distributed, and not every ash is suitable. That’s where calcined clays, volcanic tuffs, and other regionally available materials step in. Standards are catching up, shifting from prescriptive “thou shalt use cement X” clauses toward performance-based durability targets. The more specs measure permeability, chloride diffusion, and sulphate resistance directly, the easier it becomes to pick a lower-carbon binder that meets the numbers.

Contractors worry about consistency, rightly so. The cure is routine: certify sources, prequalify mixes, and insist on mock-ups. Once a region establishes reliable supply chains for blended binders, designers stop treating them as exotic.

Practical playbook: a Roman-inspired binder for now

There’s no single formula, but a workable pattern emerges for many applications:

- Target a substantial clinker replacement with natural pozzolan or calcined clay—often 30–50% by mass of binder, higher in mass concrete.

- Specify low water-to-binder ratios and good curing practice to ensure the pozzolanic reaction proceeds and pores stay fine.

- Use graded aggregates to reduce paste demand; every kilogram of paste avoided is carbon avoided.

- In marine or de-icing salt exposure, add a diffusion-based durability criterion (e.g., chloride migration/rapid chloride tests) rather than relying on prescriptive cover alone.

- Consider stainless, coated, or FRP reinforcement in the most aggressive zones, minimising the corrosion burden the binder has to fight.

What about carbon capture and novel cements?

Roman-style blends don’t replace the need for carbon capture at cement plants, electrified kilns, or next-generation binders. They work alongside them. Capture tackles process emissions; electrification squeezes fuel emissions; pozzolans and calcined clays cut clinker demand immediately. The fastest path to meaningful reductions is to use all the tools we already have while the next ones mature.

There’s also a place for alkali-activated binders and other novel chemistries, especially in precast, where curing conditions are controlled. But in cast-in-place work with mixed exposure and tight schedules, the least disruptive move often starts with a Roman-style blend you can pour with familiar equipment.

Life-cycle accounting that tells the truth

If you measure only the emissions at the plant gate, you miss the main show. Life-cycle assessments that include maintenance cycles, traffic closures, and replacement intervals are kinder to durable binders because they reflect reality. A quay that earns an extra forty years before major rehabilitation avoids not just the emissions of a rebuild but also the logistical emissions of cranes, barges, and detours. Clients are receptive to this when the model is plain and the risk is documented.

Culture change on site

Teams that succeed with blended binders do a few simple things differently. They plan for curing, protect surfaces from early drying, and resist the urge to value-engineer away the very features that buy longevity. They also keep an eye on finish expectations: pozzolanic pastes can behave differently under the trowel. None of this is hard; it’s a matter of habit.

Engineers sometimes call durability “the orphan property” because no one owns it until something fails. Roman-style mixes invite a different mindset: treat durability as a first-class design target, measure it, and reward it. When that becomes normal, emissions quietly fall across the portfolio because you rebuild less.

Case logic, not case studies

You don’t need a trophy project to justify a better binder. Take a mid-rise parking structure a few miles from the coast. The standard mix hits strength early but invites chloride ingress; the deck starts spalling within fifteen years. Swap in a pozzolan-rich binder, adjust the schedule, and you push that first major repair far down the road. Or consider a rural bridge with limited access for maintenance: slower early gain is a small price for an extra twenty years without a lane closure.

In other words: argue from exposure, use, and access. The carbon math follows.

What the Romans can’t teach us

Rome didn’t have high-rise cores, post-tensioned slabs, or traffic barriers that must open three days after a pour. We do. The point isn’t to romanticise the past; it’s to borrow the parts that make sense for our constraints. Keep Portland cement where you need it; replace it where you don’t. Keep steel where it’s essential; protect it ruthlessly where it’s vulnerable. Use the slowness of pozzolans as a design parameter rather than an irritation.

Put like that, Roman concrete ceases to be a museum piece. It becomes a set of habits: choose reactive fines, cure properly, design for the site, measure durability honestly. Do those things and your structures live longer—and that, more than anything, is a climate strategy you can build on.